CELLULOSE ACETATE GRANULES

Injectable nature

-

What is Cellulose Acetate+Cellulose is a natural polymer obtained from vegetable cellulose. By reacting cellulose with acetic anhydride Cellulose Acetate is obtained. Plasticizers are then added to Cellulose Acetate to improve its physical characteristics and workability.

-

The range of our granules+

The offer of Mazzucchelli 1849 Cellulose Acetate granules differs in quality, process, formulations and color range and are marketed under different trademarks.

PLASTILOID® granules offer a wide range of colors and plasticizers, between 18% and 40%, and are suitable for different applications, ranging from fashion items (jewelry, eyewear) to more typically industrial products.

SETILITHE® granules, on the other hand, are more specifically formulated for technical applications, such as tool handles or filters and cups for oils and greases.

M49® is the trademark for biodegradable Cellulose Acetate granules, produced on the basis of an exclusive patent, whose content of natural components reaches about 70%.

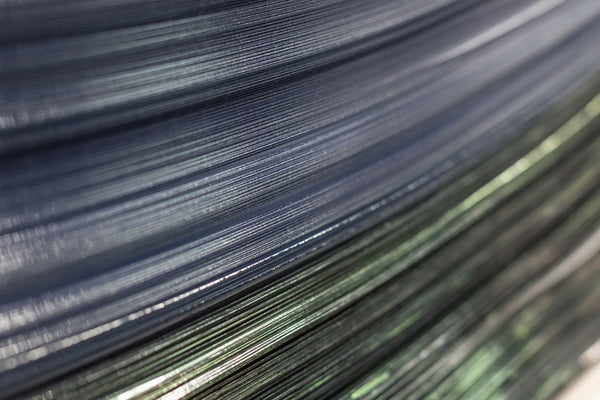

The granule is the primary form for transformation through the processes of sheets and films extrusion, injection molding, molding and extrusion blow molding of hollow corps.

That small granule contains all the green and sustainable potential for the production of cosmetic packaging, clothing accessories, costume jewelry and many other applications.

This is because Mazzucchelli’s granule is made of Cellulose Acetate. Cellulose is a natural polymer which represents the backbone of the whole plant kingdom.

The range of our granules offers multiple hardnesses and countless colors in order to satisfy all technical and aesthetic needs.

The granule born of nature

Cellulose Acetate is already a surprising material for its green component, but with M49 we have taken a further step towards sustainability by replacing the traditional plasticizer with a plasticizer of vegetable origin, thus making M49 a bioplastic with a remarkable bio-based content. The resulting formula is mostly composed of materials deriving from renewable sources.

Difference between Cellulose Acetate and M49 Bioplastic Renewable sources Responsible forest management Biodegradability

Sustainable not only as a material, but as a philosophy

Imagine if you can add recycled content to the bio content, thus creating a green material that is sustainable throughout its entire life. All of this is possible thanks to Acetate Renew obtained through Eastman's CRT technology combined with our M49 Bioplastic formula. As a matter of fact from this combination it is possible to produce cellulose acetate granules starting from a flake obtained from waste.

Acetate Renew Cellulose Acetate flake Mass balance certification Sustainability

Green by its very nature but in any color you desire

We love creativity to be green and green to be creative. That’s why with our granules you will have endless possible colors at your disposal, as color is part of our DNA. Besides this, the natural origin of raw materials provides the products with a set special of features hard to find in synthetic resins.

Range of colors and product featuresWe give you the granule,

you make the transformation

-

Indicative injection molding conditions of granules+

-

Technical features of Cellulose Acetate granules+

-

Technical features of M49 Bioplastic granules+

The granule is the primary form for transformation through the processes of sheets and films extrusion, injection molding, molding and extrusion blow molding of hollow corps. The range of our granules offers multiple hardnesses and countless colors in order to satisfy all technical and aesthetic needs.

For any information we are at your disposal and you can contact us at info@mazzucchelli1849.it

As previously said, Cellulose Acetate is a natural polymer obtained from vegetable cellulose, the most widely spread organic compound in nature. By reacting cellulose with acetic anhydride Cellulose Acetate is obtained. Plasticizers are then added to Cellulose Acetate to improve its physical characteristics and workability.

Traditional plasticizer used for Cellulose Acetate has been replaced by a plasticizing solution of vegetable origin, thus making M49 a bioplastic with a remarkable bio-based content.

Raw materials used in M49 formulation are Cellulose Acetate deriving from wood and a plasticizer based on citric acid ester mainly derived from vegetable starch and bioethanol.

The quantity of product deriving from renewable sources is expressed as a percentage and provides an indication of how much part derives from renewable sources and how much from fossil sources.

The reference test is ASTM D6866: an analytical method developed to measure renewably-sourced content of solids, liquids, and gaseous samples using 14C radiocarbon dating.

With this method the Percent Modern Carbon (pMC), or organic carbon, derived from biomass, is distinguished from carbon deriving from fossil fuels since the latter is devoid of the 14C isotope.

M49 has undergone this analysis and the content of natural origin reaches 68%.

Download CertificateThe Cellulose Acetate used by Mazzucchelli for M49 comes from wood whose cultivation and harvest are managed according to the guidelines of the Association for the responsible management of forests - Forest Stewardship Council (FSC).

FSC is an international non-governmental organization established in 1993. The Responsible Forest Management certification released by this organization ensures that a forest or plantation is managed in compliance with rigorous environmental, social and economic standards valid throughout the world.

The degree of biodegradation of M49 exceeds 90% already after 115 days of incubation and is therefore biodegradable (according to the UNI-EN-ISO 14855-2: 2018 standard).

According to the International Organization for Standardization, the term biodegradable is used to define any material that can be broken down by the enzymatic activity of microorganisms, sunlight and other environmental physical agents, into simple chemical compounds such as water, carbon dioxide and methane. Biodegradation is influenced by the chemical nature of the material to be biodegraded and by the biodegradation environment. In order to define a plastic material as biodegradable, the degree of biodegradation must reach 90% in an incubation time of no more than 6 months.

Download CertificateAcetate Renew is the flake used to produce our granules and is made through Eastman's innovative Carbon Renewal Technology, which consists of breaking down plastic waste into primary molecules for the synthesis of more complex organic molecules.

In other words, plastic waste, instead of being sent to landfills, is treated by Eastman and reconverted into Syngas, a mixture mainly composed of carbon monoxide and hydrogen, and from these elements other primary chemical products are synthesized which, in the case of Cellulose Acetate, is acetic anhydride.

Cellulose Acetate flake is to be considered sustainable at 60%, a percentage which corresponds to the cellulose content. The remaining 40%, in fact, consists of Acetic Anhydride of fossil origin. With Acetate Renew the degree of sustainability has reached 100%, since 40% of recovered Acetic Anhydride has been added to the 60% of cellulose. Moreover, using Acetate Renew reduces by 20% – 50% greenhouse gas emissions.

Acetate flake and the granules produced using this new technology are neither physically nor chemically different from traditional ones.

In other words, there is no chemical or physical-mechanical test capable of distinguishing the two products. Therefore the only possibility to have a certain traceability of using products made of Acetate Renew is through a mass balance.

In order to prevent any false declaration, the mass balances along the entire supply chain, flake – granules – finished products, must be certified by an independent body. In our case it was decided to use ISCC, an international organization created with the aim of certifying sustainable processes for the environment.

Download CertificateThe natural and renewable content of M49, evaluated according to the criteria of the ASTM D6866 analysis, reaches 68% (There may be slight deviations due to formulation or process). Thanks to the addition of recycled content, the percentage of sustainability reaches 96%.

Granules have unlimited coloring possibilities, not only in terms of tone. In fact, our granules have different opacities, ranging from transparent to solid colors, you can have pearly colors as well as fluorescent ones.

In addition to the color, here below you may find the list the features that make this product unique:

- Clearness and brightness

- Good impact resistance

- Excellent electrical insulation properties

- Excellent chemical resistance to oils and grease

- Very good resistance to light and ageing

- A pleasant touch and a self-smoothing surface

- Excellent acoustical qualities and sonority close to that of the wood

Product succesfully added to cart