Material, processing and storage

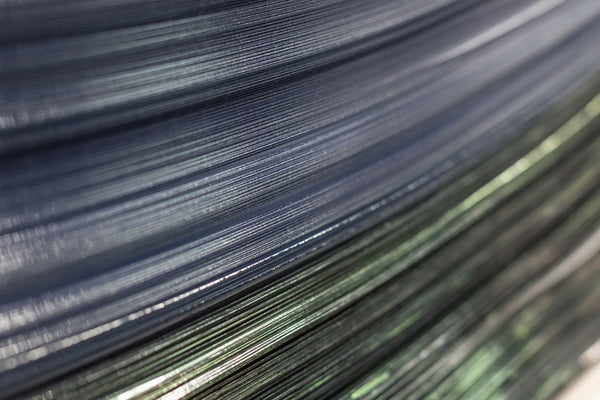

Cellulose is a natural polymer from vegetable cellulose. Cellulose Acetate (CA) and Cellulose TriAcetate (CTA) are obtained by reacting cellulose with acetic anhydride, whereas Cellulose Propionate (CP) is obtained by reacting cellulose with a mix of acetic anhydride and propionic anhydride. Different plasticizers are then added to Cellulose Acetate and Cellulose Propionate to improve their physical characteristics and workability. Through sophisticated extrusion and press polishing processes we obtain sheets with high optical quality suitable for various technical and protective purposes.

Our Cellulose Acetate, Cellulose TriAcetate and Cellulose Propionate sheets are supplied with protective film on both sides. It is advisable to keep the sheets protected with the film until the end of the whole manufacturing process. Generally, this consists of cutting, thermoforming and assembly into the final product. Being Cellulose Acetate, Cellulose TriAcetate and Cellulose Propionate polymers of natural origin and sensible to temperature and humidity, we recommend keeping the material for at least 24 hours in the same environment as the working place before processing, ideally at around 20-25 °C and 45-55% relative humidity.

PROCESSING

- Cutting into lenses/visors: generally, this operation is performed by punching, milling or laser cutting.

-

Thermoforming into cylindrical or spherical shape: to avoid that imperfections in the protective film or in the thermoforming tool are transferred into the lens / visor, it is advisable to keep the temperature of the tool below the softening temperature of the CA or CP sheet material. The recommended temperatures are following:

- CA: 75-80 °C

- CP: 80-85 °C

If the result is not yet satisfactory it is advisable to lengthen the heating time rather than increasing the temperature.

STORAGE

The Cellulose Acetate, Cellulose TriAcetate and Cellulose Propionate sheets should be kept in their original boxes, placed in horizontal position by not stacking more than 5 boxes one on top of each other. The material should be stored in a conditioned environment at 20-25 °C and 45-55% relative humidity. Make sure that the material is not exposed to heat, humidity, direct light and dust.