Materials and processing

What is an Mdecor thin sheet

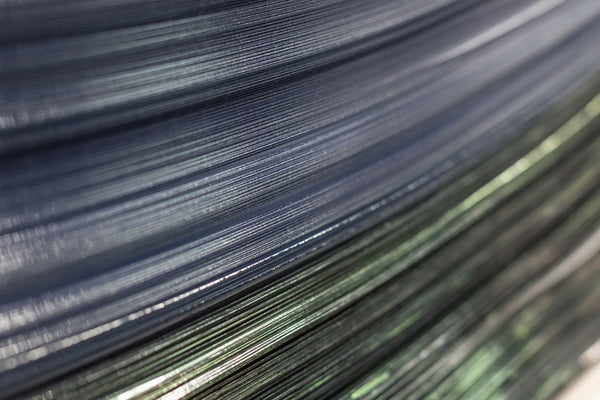

Mdecor is a decorative flexible film made of aliphatic TPU produced with Mazzucchelli block technology, a technology which allows to obtain unique and inimitable pearlescent and three-dimensional effects notwithstanding a very tiny thickness.

The Mdecor thin sheets you will find in this selection have a gross size of 63 x 145 cm. The edges, which may be irregular, can be removed, if necessary, thus reaching a net size of 60 x 140 cm. Thickness is 0.2mm.

Mdecor thin sheets finishings are defined RR, LM and MM. You can thus decide to have sheets with both rough sides (RR), with one glossy and one matte side (LM) or with both matte sides (MM). The RR finishing is suitable for applications where Mdecor needs to be laminated or reworked. The LM and MM finishing allow you to use the sheet as it is.

All sheets are supplied with a removable sticker with product code on it.

Mdecor – TPU films

Mdecor is a decorative film made of aliphatic TPU.

It can be used in many ways and for various applications, whenever there is a need for special aesthetic effects, higher performances and longer product life, exceptional resistance to hydrolysis and UV exposure, flexibility in a wide range of temperatures and good resistance to microorganisms.

Mdecor can easily be hot and high frequency welded, sewn or glued; and is compatible with different materials such as plastics, wood, metal, fabric, paper and non wovens.

Finishing

Rough, glossy and matte surface: Our Mdecor sheets come out of production with both sides rough (RR), perfect if you need to laminate or rework them. Alternatively, you can choose to have the material with one glossy side and one matte side (LM), or with both matte sides (MM). In this case the sheets will be subjected to a pressing process that will allow to transform the raw surface into a perfect matt (M) and glossy (L) finishing.

Therefore, our sheets can have the following finishing:

RR: both sides rough.

LM: one glossy side and one matte side.

MM: both matte sides.

Composition with other materials

You can combine Mdecor with different types of materials to create your original products.

- Lamination: Mdecor can be laminated with many substrates including other plastic materials such as PC, ABS, PMMA, Acrylates, PVC and TPU itself as well as canvas, non-woven fabrics, paper, cardboard and leather. If needed, TPU is compatible also with adhesives such us EVA, PVB, etc.

- Technical lamination with other polymers gives different characteristics to Mdecor such as rigidity, thickness, scratch resistance or anti-stick properties and thermoforming.

- Aesthetical lamination with colored or printed plastic films can modify the aesthetical appearance creating a wider variety of effects. We recommend not to use temperatures exceeding 140°C to avoid damages to the pattern.

- Bonding: adhesives can be used to bond Mdecor on many substrates. We suggest to use epoxy or reactive polyurethane glues.

- Welding: Mdecor is easily weld-able with high frequency, alternatively it can be hot air welded, for instance to canvas and fabrics.

- Sewing: the tear resistance of Mdecor makes the material sewable without being ripped and torn.

Cutting

Mdecor can be easily cut to obtain all the shapes you want.

- Cutting: Mdecor can be cut using normal tools such as cutters, scissors, punches, trimmer, shears, circular or band saws.

- Laser cut: thanks to the absence of plasticizers, Mdecor can be also laser cut, even when it is laminated with other materials compatible with laser cut. Mdecor can also be laser engraved. Our R&D team can help you to find the right conditions for laser cutting.

Shaping

Mdecor, alone or in combination with other materials, can be shaped by thermoforming and over-injection.

- Thermoforming: Mdecor can be thermoformed after laminating with rigid sheets of thermoplastic polymers such as Polycarbonate, Acrylates, PVC, Polyamides and so on. Those laminates can be thermoformed even with only a single mould. Thermoforming conditions can vary according to thickness, composition and complexity of the shape. Ideal processing temperature is between 120°C and 140°C. We recommend not to use temperatures exceeding 140°C for a long time to avoid damages to the pattern.

- Over-injection: Mdecor is also suitable for over-injection, notably with PU. We recommend not to use temperatures exceeding 140°C for a long time to avoid damages to the pattern.

Mdecor can be printed with different techniques. As a matter of fact, our thin sheets can be hot stamped or silk screen printed in order to offer you the possibility to create your own customization.

Handling and Storage

Easy to store.

Mdecor is made with aliphatic TPU at high light stability. Anyway, we recommend to pull out the sheets from the tube as soon as you receive your order and to store them in a horizontal position, in a dry environment and protected from direct light and heat sources, keeping paper sheets between to avoid any damage and sticking.