OUR MATERIAL FOR VISORS

when perfect visibility without fog is essential

Polymers of natural origin

-

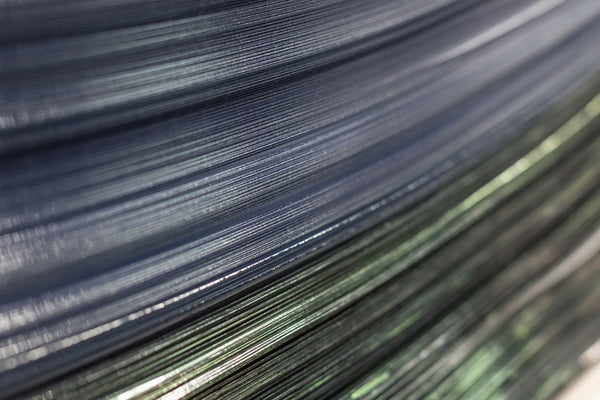

Cellulose Acetate (CA) – trademark Xelox-L+

Cellulose is a natural polymer from vegetable sources. Cellulose Acetate (CA) is obtained by reacting cellulose with acetic anhydride. Different plasticizers are then added to Cellulose Acetate to improve their physical characteristics and workability. Through sophisticated extrusion and press polishing processes we obtain sheets with high optical quality suitable for various technical and protective purposes.

Download CA General Properties -

Cellulose Propionate (CP) – trademark Worblex+

Cellulose Propionate (CP) is obtained by reacting cellulose, a natural polymer which represents the backbone of the whole plant kingdom, with a mix of acetic anhydride and propionic anhydride.

Download CP General Properties

The physical properties and workability of cellulose propionate are then improved by the addition of plasticizers. We are able to produce sheets with high optical quality which are suitable for a variety of technical and protective purposes through advanced extrusion and press polishing processes. -

Cellulose TriAcetate (CTA) – trademark Xelox-L+

Cellulose TriAcetate (CTA) is produced by reacting cellulose with acetic anhydride. It then undergoes a sophisticated casting processes which allows to produce sheets with high optical quality which are suitable for a variety of technical and protective purposes.

Download CTA General Properties

There TriAcetate sheets are polarized.

In an increasingly technological world, where high performance and quality are required in the most diverse sectors, nature comes back to help us. This is how thanks to polymers of natural origin it is possible to produce sheets able to offer those technical characteristics necessary to produce visors for optical applications.

Superior anti-fog performance

Whether you’re working or driving or swimming you need to be able to see clearly. A fogged-up vision can significantly compromise several daily activities and, in many cases, can increase the risk of injury.

That’s why an anti-fog system is needed to help you to achieve a clearer vision thus making sure that you can carry out your activities with precision and accuracy.

Mazzucchelli has developed in its laboratories an anti-fog system which will prevent its products from fogging up guaranteeing a protection which will last forever.

Eye protection in optical quality

The good physical and mechanical properties, their resistance to chemicals and solvents combined with a variety of additional features make our Cellulose Acetate, Cellulose TriAcetate and Cellulose Propionate sheets the ideal solution for eye protection.

Find out the technical features of our sheets.Applications

The technical characteristics of our sheets, the high standards of quality that characterize them and their physical and mechanical properties make them suitable for the following applications:

- Lenses for ski goggles

- Lenses for goggles and visors for industrial and medical safety

- Lenses for swimming goggles

- Visors for motorcycle helmets

We have a solution for every need of our customers.

-

Find out our MOQs+

Being there a high number of possible variables, we do not supply from the shelf, but all materials are produced against order and according to the specification requested by the client and with following MOQ (minimum order quantity):

- Clear – 100 kg

- Coloured – 250 kg

- Photochromic – 100 kg

- Polarized Triacetate – 200 sheets

-

Technical specifications of our sheets+

Sheet sizes

SURFACE FINISH SP SA AP & AW Size for CA and CP mm 620 x 1420 590 x 1380 620 x 1400 Size for CTA mm 320 x 1400 — 320 x 1400 Tolerance mm ± 10 ± 10 ± 10

Thicknesses

SURFACE FINISH SP SA AP AW Thickness for

CA and CP mm0,5 - 3,5 0,6 - 1,6 0,5 - 3,0 0,6 - 3,0 Thickness for

CTA mm0,65 - 1,2 — 0,65 - 1,2 — Tolerance % ± 10 ± 10 ± 10 ± 10

We have a solution for every need. We know that each application requires different grades and that’s why we follow you step by step in choosing the ideal solution for you.

For any further information and consultancy you may need about the most appropriate grade for your intended application and to request detailed Technical Data Sheets, please contact Mr. Ingo Alexy at the following email address: ialexy@mazzucchelli1849.it.

The exposure of the Cellulose Acetate, Cellulose TriAcetate and Cellulose Propionate sheets to a multi-step chemical reaction makes their surface resistant to fogging which becomes an inherent property of the sheets. The hydrophilic surface enables the sheets to absorb moisture vapor without fogging up and leaving a clear view through.

Thanks to this process the following results can be achieved:

- For the standard grade a fog-free time of ≥ 30 seconds is guaranteed in accordance to ISO 16321-1 7.13, ISO 18527-1 14.2 and ISO 18527-3 9.4.

- For special applications we can offer our “super-anti-fog” grade with improved fog-free time of ≥ 120 seconds.

- The anti-fog performance lasts forever.

Here is a list of the features that make our Cellulose Acetate, Cellulose TriAcetate and Cellulose Propionate sheets so effective for eye protection in optical quality:

- Light transmittance up to 90%

- UV protection at 360 nm, 380 nm and 400 nm

- Good mechanical resilience at low temperatures

- Good resistance to chemicals and solvents

- Gas welding filters up to shade 5, with or without IR protection up to 1400 nm

- Laser protection filters

- Blue light blockers

- Wide range of colour tones

- Highly active photochromic colours

- Polarized colours