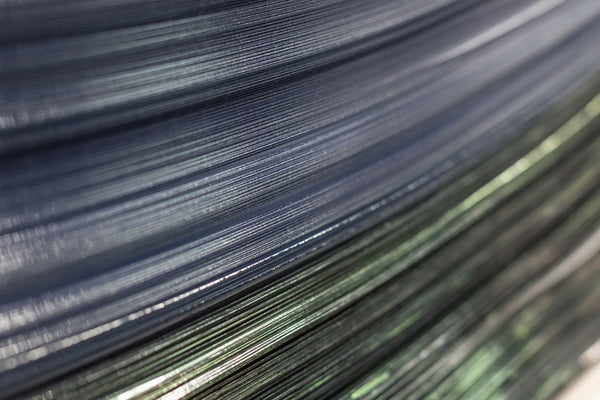

Biocomposites granules

Granules with textile and agro-food waste

Circularity and Innovation

The biocomposite acetate granules offered by Mazzucchelli are the result of true circular innovation: starting from cellulose acetate, we enrich it with natural or recycled materials, such as agro-food and textile waste. The result? Sustainable, high-performance materials that give new life to what would otherwise be discarded, telling a genuine story of sustainability.

Reuse of textile and agro-food waste

By using waste that would otherwise be sent to landfill, Mazzucchelli reduces the environmental impact of the industrial supply chains involved. Typically, up to 20% of residual materials can be incorporated into our formulations.

The additives are sourced from processing centers as close as possible to our facilities to minimize transportation impacts.

Our granules incorporate:

- Waste from denim, cotton, and viscose fabric production

- Residues from various wood processing operations

- Waste from agro-food processing, including rice and tobacco

- Recovered spent coffee grounds

- Other plant-based components

Mazzucchelli’s careful approach to compounding significantly reduces the material’s carbon footprint.

Measurable sustainability performance

We can use as the base component either the standard cellulose acetate formulation, the M49 or M49 TEC versions to achieve different sustainability percentages depending on design requirements. As with all other Mazzucchelli granules, biocomposites can also be recycled after use, either through conventional recycling or molecular recycling (CRT).

No limits to processing

Mazzucchelli biocomposite granules are designed to perfectly adapt to the most common processing technologies, such as injection molding and extrusion, offering maximum production versatility.

To make the product even more sustainable, we recommend using biocomposite granules in their natural color, derived from the incorporated recycled material, avoiding the addition of extra pigments and dyes. However, if desired, it is possible to modify the color within the limits of the added components.

Applications of biocomposite granules

Mazzucchelli biocomposite granules are the result of a research and innovation journey aimed at extending the use of cellulose acetate well beyond the traditional boundaries of eyewear, offering an extremely flexible material suitable for various sectors such as cosmetic packaging, fashion jewelry, and numerous other applications where sustainability and aesthetic quality are key elements.

Mazzucchelli’s ability to tailor the properties of biocomposite granules to different design requirements allows for customized solutions that combine technical performance, strength, transparency and a natural tactile feel in a single material. Born from continuous research and development, Mazzucchelli biocomposites embody a circular approach and the reduction of fossil raw material use.

Thanks to the company’s expertise in processing acetate, Mazzucchelli is now able to provide sustainable materials that offer a concrete alternative to traditional plastics and support the evolution of multiple industrial sectors toward a more responsible and innovative future.

| Std granules | M49 granules | M49TEC granules | Biocomposites | |

|---|---|---|---|---|

| Fashion accessories | Sì | Sì | Sì | Sì |

| Eyewear | Sì | Sì | No | Sì |

| Cosmetic packaging | Sì | No | Sì | Sì |

| Tooling | Sì | No | Sì | No |

| Personal accessories | Sì | Sì | Sì | Sì |

| Oil containers | Sì | No | No | No |

| Extrusion products | Sì | Sì | No | Sì |

| 3D printing | Sì | Sì | Sì | No |

To explore the potential and application fields of acetate biocomposite granules, visit the dedicated applications section.

Bring Mazzucchelli innovation to your industry

If you’re interested in using our granules, you can contact us to receive dedicated consultation, technical insights, or request material samples.

Why choose Mazzucchelli 1849 granules

Relying on Mazzucchelli means choosing a global benchmark in the processing of M49 cellulose acetate — a company that for generations has set the standards of excellence,innovation, and sustainability in the field of high-quality materials.

Through continuous research into alternatives to traditional plastics, Mazzucchelli develops cutting-edge solutions capable of meeting the needs of constantly evolving markets: from design to eyewear, from cosmetic packaging to advanced technical applications.

Collaborating with Mazzucchelli means gaining access to the latest sustainable technologies, the result of rigorous experimentation, validated by a team of experts who support customers at every stage of the project, from material selection to final production.

What makes Mazzucchelli unique on the international stage is its combination of historical expertise and innovative vision, a balance that translates into:

- Over 175 years of know-how in cellulose acetate processing.

- Innovation and sustainability as the guiding principles behind every development.

- Fully controlled and traceable production processes.

- Personalized technical support and ongoing consulting.

- International certifications and recognitions confirming the brand’s reliability.

Choosing Mazzucchelli means relying on a solid, forward-thinking, and highly specialized partner capable of transforming matter into value and guiding every project toward a more sustainable and innovative future.

Certified Reliability

The quality of our cellulose acetate granules is confirmed by internationally recognized certifications that attest to compliance with environmental, safety and resource management standards.

All materials used comply with REACH, RoHS and Proposition 65 regulations, which govern chemical safety and the restriction of hazardous substances, ensuring the protection of human health and the environment.

In addition, the materials have undergone rigorous dermatological testing to ensure their compatibility with prolonged skin contact (ISO 10993).

A concrete commitment to transparency, traceability, and sustainability throughout the entire supply chain.

Other Mazzucchelli acetate granules

In addition to Biocomposites granules, Mazzucchelli’s offering includes:

FAQ

-

What are Mazzucchelli biocomposites?+Biocomposites are cellulose acetate–based granules to which we can add plant-based fillers from various recovery and recycling sources, such as residues from agro-food or textile processing.

-

Which types of cellulose acetate are used for biocomposites?+All grades of cellulose acetate can be used, from the standard formula to M49 and M49TEC. The plasticization percentages can also be adjusted according to the physical properties required for the specific application.

-

Does Mazzucchelli 1849 provide support in developing products with biocomposites?+Mazzucchelli 1849’s technicians assist customers in selecting the best granule formulation, also based on the content and type of material to be added to the base granule. Mazzucchelli 1849’s laboratories can provide analysis and prototyping of new granules specifically developed for our clients.

-

Which recovered materials are used in Mazzucchelli biocomposites?+We can use different materials derived from agro-food or textile processing waste that would otherwise be destined for disposal or landfill, helping reduce environmental impact within a circular economy process. Examples include coffee grounds, rice husk, tobacco, wood and denim or viscose scraps.

-

Can biocomposite granules be colored?+Biocomposites can be colored, with some limitations depending on the type of additive component. We usually recommend using granules that retain the natural color of the recovered material added (e.g. denim, tobacco, coffee, etc.), which also eliminates the need for pigments or dyes, making the product even more sustainable.

-

Where can biocomposite granules be used?+Applications are numerous, as with other cellulose acetate–based granules. In particular, they are ideal for use in object design, personal care accessories and cosmetic packaging.

-

Is Mazzucchelli 1849 ISO 9001 certified?+Yes. In addition to ISO 9001 certification, Mazzucchelli also holds ISCC PLUS certification for materials produced using Acetate Renew/CRT (Carbon Renewal Technology) raw materials.

-

Can I request samples and brochures?+Mazzucchelli 1849 is available to provide complete technical information about its products and to supply samples of the materials it manufactures.