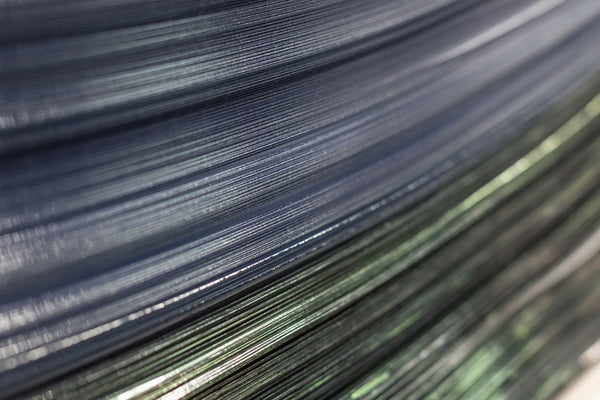

Standard cellulose acetate granules

The first step toward sustainability

Technology, aesthetics and sustainability: the identity of Mazzucchelli standard acetate

Standard cellulose acetate granules represent one of the most established sustainable alternatives to plastics of fossil origin. Cellulose acetate is a plastic material derived from cellulose, the backbone of the entire plant kingdom, obtained mainly from wood pulp.

By reacting cellulose with acetic anhydride Cellulose Acetate is obtained. Plasticizers are then added to Cellulose Acetate to improve its physical characteristics and workability. The introduction of this material has historically represented a valid alternative to many common plastics, finding wide use in fashion, design, tooling and eyewear thanks to its versatility and high performance.

From an environmental point of view, standard cellulose acetate granules contain more than 40% of renewable content, due to the cellulose. Their sustainability increases further thanks to the possibility of recycling them either mechanically or through molecular recycling processes (CRT – Carbon Renewal Technology).

While mechanical recycling can reduce coloring options and performance of the final product, molecular recycling makes it possible to obtain articles indistinguishable from virgin material, retaining perfect transparency. Thanks to CRT technology, the total sustainability level (that is the contact of bio-based + recycled content) of cellulose acetate granules reaches 67%.

In addition, the cellulose acetate used by Mazzucchelli is derived from wood grown and harvested under the guidelines of Forest Stewardship Council (FSC), an international non-governmental organization founded in 1993, thus ensuring that forests are managed according to rigorous environmental, social and economic standards.

All this makes standard cellulose acetate granules a more responsible choice than traditional polymers and a concrete commitment to a more conscious production future.

Standard cellulose acetate granules stand out for their technical and mechanical properties, which make them particularly versatile. The material is strong, durable and easy to process and color. Cellulose is transformed into a highly adaptable transparent material that can be colored in thousands of shades — transparent, translucent, pearlescent, milky or solid. It offers a universe of aesthetic and chromatic possibilities that combine creative freedom with sustainability, ensuring the highest level of performance.

These characteristics make it suitable for a wide range of applications across various sectors — from fashion accessories to design components, as well as technical and industrial products. By combining aesthetics, functionality and environmental responsibility, standard cellulose acetate granules represent an advanced product designed for applications that require sustainable materials with high aesthetic value.

Choosing Mazzucchelli granules therefore means relying on a material that combines technical excellence, natural beauty and environmental respect, offering a concrete solution for those seeking a modern, reliable and responsible plastic.

Properties and Advantages of cellulose acetate granules

Compared to traditional plastics, cellulose acetate offers a valid and high-performance alternative for many applications. Its sustainability and environmental advantages are significant both because it is partially derived from renewable resources and because it is easier to process than fully synthetic plastics.

| Std Acetate | PE/PP | ABS | PET/PC | PLA | M49 | |

|---|---|---|---|---|---|---|

| Sustainability | medium | medium | low | medium | high | high |

| Trasparency | high | medium | low | high | low | high |

| Coloring | high | medium | low | high | medium | high |

| Impact resistance | medium | medium | high | high | low | medium |

| Biodegradability | medium | low | low | low | high | high |

The production processes of cellulose acetate require less energy than most plastics and offer unique versatility in the design and manufacture of final products, with significant resource savings. Their refined appearance, both visual and tactile, is exclusive and incomparable to any other plastic on the market, providing a material suitable for a wide range of high-quality applications.

Its superior transparency and colorability also make it unique among bioplastics.

Processing and applications of granules

Standard cellulose acetate granules are designed to guarantee maximum processing flexibility and are suitable for major polymer transformation technologies such as extrusion, injection molding, blow molding and 3D printing. They can be processed using standard production lines already in use for other polymers, simplifying integration into existing processes.

Their formulation versatility allows the plasticizer content to be adjusted to calibrate hardness, resistance and flow according to specific application needs, ranging from eyewear and fashion accessories to tools, packaging and industrial oil containers.

This expansion into new fields is the result of Mazzucchelli’s continuous research and innovation. For over 175 years, the company has invested in the development of sustainable and high-performance materials, aiming to offer concrete alternatives to traditional plastics for a more responsible future.

| Std granules | M49 granules | M49TEC granules | Biocomposites | |

|---|---|---|---|---|

| Fashion accessories | Sì | Sì | Sì | Sì |

| Eyewear | Sì | Sì | No | Sì |

| Cosmetic packaging | Sì | No | Sì | Sì |

| Tooling | Sì | No | Sì | No |

| Personal accessories | Sì | Sì | Sì | Sì |

| Oil containers | Sì | No | No | No |

| Extrusion products | Sì | Sì | No | Sì |

| 3D printing | Sì | Sì | Sì | No |

Discover all the details about the possible applications of the material by visiting the page dedicated to the applications of standard cellulose acetate granules.

Bring Mazzucchelli innovation to your industry

If you’re interested in using our granules, you can contact us to receive dedicated consultation, technical insights, or request material samples.

Why choose Mazzucchelli 1849 granules

Choosing Mazzucchelli 1849 granules means relying on a world-leading company in the processing of cellulose acetate. With over 175 years of experience, Mazzucchelli today combines tradition and innovation, offering its clients reliable, cutting-edge solutions for every application sector.

Mazzucchelli’s recognized quality is based on:

- Historical Expertise: Since 1849, Mazzucchelli has led the evolution of materials, becoming a symbol of quality and know-how.

- Innovation and sustainability: The company continuously invests in research and development, offering products designed to meet the needs of a market increasingly focused on environmental awareness and the responsible use of resources.

- Strict quality control: very production batch undergoes rigorous quality checks to ensure compliance and high performance.

- Customer Service and Technical Support: A dedicated team assists clients at every stage, providing both technical and commercial support.

- Certification: Mazzucchelli 1849 has always combined quality, innovation, and sustainability, earning several certifications over the years.

Certified Reliability

The quality of our cellulose acetate granules is confirmed by internationally recognized certifications that attest to compliance with environmental, safety and resource management standards.

All materials used comply with REACH, RoHS and Proposition 65 regulations, which govern chemical safety and the restriction of hazardous substances, ensuring the protection of human health and the environment.

In addition, the materials have undergone rigorous dermatological testing to ensure their compatibility with prolonged skin contact (ISO 10993).

A concrete commitment to transparency, traceability, and sustainability throughout the entire supply chain.

Other Mazzucchelli acetate granules

In addition to standard acetate, Mazzucchelli’s offering includes:

FAQ

-

Can cellulose acetate granules be colored?+Cellulose Acetate Granules can be colored in endless shades to obtain transparent, translucent, opaque or pearlescent products.

-

Can I customize cellulose acetate granules?+Our granules can be tailored to the customer’s specific application by adjusting the type and amount of plasticizer to achieve different physical–mechanical and sustainability characteristics. In addition, we can produce an infinite range of color variations.

-

In which sectors can cellulose acetate granules be used?+Our granules are the ideal choice for creating sustainable and functional products in the fashion accessories, packaging, tooling, home décor and personal accessories sectors.

-

Does Mazzucchelli 1849 provide consulting for product development using cellulose acetate granules?+Mazzucchelli 1849’s technicians work closely with customers to fine-tune granule formulations according to machinery and final application requirements. The company’s laboratories can perform analyses and prototype new granules specifically developed for our clients.

-

Are Mazzucchelli granules certified?+Mazzucchelli 1849 standard granules comply with REACH, RoHS and Proposition 65 regulations, contain no PFAS and are tested according to ISO 10993 to ensure compatibility with prolonged skin contact.

-

How can I contact Mazzucchelli 1849 to request consulting or samples?+You can contact Mazzucchelli 1849 by phone during business hours, by email, or through the dedicated contact form.

-

Is Mazzucchelli 1849 ISO 9001 certified?+Yes. In addition to ISO 9001 certification, Mazzucchelli also holds ISCC PLUS certification for materials produced using Acetate Renew/CRT (Carbon Renewal Technology) raw materials.

-

What are the differences between cellulose acetate and traditional plastics?+Cellulose acetate has a high sustainability content because it is partially derived from renewable resources and requires less energy to process than fully synthetic plastics. Its touch, aesthetics and color brilliance distinguish cellulose acetate products from those made with other plastics.

-

Can I request samples and brochures?+Mazzucchelli 1849 is available to provide complete technical information about its products and to supply samples of the materials it manufactures.