Applications of acetate granules

A granule holding infinite possibilities.

It is incredible what can be created from a small granule. Thanks to the various formulations available, designed to meet highly specific needs, to its endless color options and to its technical properties you can select the most suitable material for your project, whether in fashion, design, eyewear, technical items or industrial components.

Each formulation is developed to offer precise performance: mechanical strength, transparency, workability, aesthetic effect, sustainability and innovation.

Fashion accessories

Where creativity has no limits, materials must offer an infinite range of colors, refined finishes and great versatility, allowing the creation of small or large objects, simple or complex, always with distinctive aesthetics. Mazzucchelli’s acetate granules for fashion jewelry perfectly meet these needs: they allow the creation of unique, resistant and long-lasting accessories that maintain brilliance and quality over time.

Cellulose acetate easily adapts to the main processes used in the sector, injection molding, laser cutting, engraving, and polishing, making it possible to obtain unparalleled color effects.

Mazzucchelli is recognized as the global leader in cellulose acetate processing for fashion jewelry, thanks to decades of experience and materials chosen by international brands for creative, high-quality collections. Thanks to its chromatic versatility, ease of processing, resistance, lightness and natural sustainability, Mazzucchelli acetate allows the creation of distinctive and refined accessories with flawless finishes and uncompromising quality.

Acetate granules suitable for fashion jewelry

→ Cellulose acetate granules

→ M49 granules

→ M49TEC granules

→ Biocomposites

Cosmetic packaging

For cosmetic packaging that must combine aesthetics, a refined tactile feel, quality and functionality, Mazzucchelli’s acetate granules represent an ideal solution thanks to their smooth surfaces, intense or transparent colors and excellent processability. Typical processes in the sector include injection molding, thermoforming, precision cutting, and polishing: methods that enhance both the aesthetic and technical features of the material while ensuring excellent color reproducibility.

Examples include:

- perfume caps and rings

- containers for creams and serums

- lids

- decorative components

Thanks to properties such as brilliance, natural sustainability, durability and easy transformation, Mazzucchelli granules allow the creation of distinctive cosmetic packaging that enhances the product and strengthens brand identity.

Acetate granules suitable for cosmetic packaging

→ Cellulose acetate granules

→ M49TEC granules

→ Biocomposites

Tooling

For tooling components requiring reliability, strength and durability, Mazzucchelli’s acetate granules are an extremely versatile solution. They offer resistance to oils and greases, an excellent surface touch, self-healing properties that reduce the visibility of small scratches, good electrical resistance, and, when needed, high transparency. It is the ideal material for producing high-quality screwdriver handles, voltage testers, hammer heads and mallets.

Cellulose acetate is perfectly suited to the production needs of the tooling sector, as it can be easily processed through injection molding, mechanical machining and surface finishing, resulting in products that are comfortable to the touch and highly performant even under intensive use.

Acetate granules suitable for tooling

→ Cellulose acetate granules

→ M49TEC granules

Personal care accessories

Our cellulose acetate is successfully used in the production of personal care items, particularly for the manufacture of hairbrushes, combs and toothbrush handles.

Its unmistakable tactile feel, comfortable grip and rich chromatic effects make cellulose acetate the ideal material for high-quality objects, ensuring a premium market positioning.

Cellulose acetate naturally lends itself to typical industry processes such as hot molding, laser cutting, milling, precision engraving, polishing, and lamination, allowing for the creation of refined effects.

Mazzucchelli is recognized as a leader in cellulose acetate processing thanks to its expertise, ongoing aesthetic research and strict quality control throughout every production phase. The combination of chromatic versatility, ease of processing, resistance, lightness and natural origin makes Mazzucchelli acetate the ideal choice for elegant, original accessories of impeccable quality.

Acetate granules suitable for personal accessories

→ Cellulose acetate granules

→ M49 granules

→ M49TEC granules

→ Biocomposites

Industrial oil cups

Cellulose acetate granules, thanks to their transparency and special resistance to liquid oils, are the ideal material for producing cups used in machinery that employs cold oils.

Acetate granules suitable for industrial oil cups

Eyewear

Mazzucchelli’s acetate granules for eyewear are the ideal choice for those seeking transparency, lightness and ease of processing, ensuring frames with superior comfort and refined design.

Cellulose acetate is highly adaptable, offering a wide range of colors, finishes and transparencies, and is perfectly suited to molding, cutting, and polishing techniques. Eyewear frames made with acetate are lightweight, resistant and durable, maintaining brilliance and shape over time.

The use of acetate in eyewear dates back to the early 20th century: thanks to its chromatic versatility and ease of shaping, it has become the main material for high-quality frames. Mazzucchelli, with over 75 years of experience, has led innovation and set quality standards in the industry.

Today, Mazzucchelli is the global leader in cellulose acetate processing, with acetate granules used by international brands for iconic frames, premium collections and sports eyewear. The granules guarantee uniform colors, resistance, lightness, and comfort.

Acetate granules suitable for eyewear

→ Cellulose acetate granules

→ M49 granules

→ Biocomposites

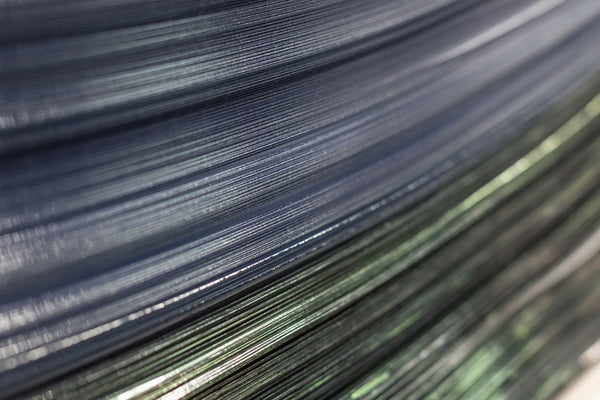

Extrusion products

Cellulose acetate is highly suitable for extrusion processes. Mazzucchelli granules, specifically formulated for technical applications, ensure uniform flow and excellent performance in both flat-die extrusion and blow extrusion, enabling precise and repeatable production.

Mazzucchelli, as a global leader in cellulose acetate processing, has decades of experience in developing formulations specifically for extrusion. The combination of consistent quality, broad color customization and mechanical performance makes Mazzucchelli acetate granules an ideal solution in sectors requiring production efficiency and flawless aesthetics.

Acetate granules suitable for extrusion

→ Cellulose acetate granules

→ M49 granules

→ Biocomposites

Printing products

Cellulose-acetate-based granules can be easily used both with 3D printers that work with filaments and with printers that operate directly from granules.

Acetate granules suitable for 3D printing

FAQ

-

What are the advantages of using cellulose acetate granules compared to other plastic materials?+Cellulose acetate granules offer an excellent balance of performance, aesthetics, and environmental sustainability, making them a valid alternative to fossil-based plastics in many applications, especially when premium design, transparency, and low environmental impact are required.

-

Are acetate granules recyclable or biodegradable?+Cellulose acetate granules can be recycled both mechanically and chemically. In addition, some Mazzucchelli formulations are also biodegradable.

-

Why is cellulose acetate particularly suitable for producing eyewear frames?+Cellulose acetate is ideal for frames because it offers extensive aesthetic customization (colors, patterns, transparencies), a glossy and brilliant surface and a unique tactile feel. It is easy to work with and adjust to any face shape. It is lightweight, resistant and flexible, ensuring comfort and durability.

-

Is cellulose acetate safe for use in jewelry that comes into contact with the skin?+Mazzucchelli uses raw materials that are not classified as allergenic and do not generally cause irritation or skin issues.

-

What are the sustainability benefits of using cellulose acetate in cosmetic packaging?+Cellulose acetate granules can contain between 41% and 97% sustainable content, depending on the formulation offered by Mazzucchelli 1849, while maintaining the transparency, tactile feel and brilliance that make our products unique.

-

What properties does cellulose acetate offer in tools compared to other plastics?+Mazzucchelli’s acetate granules for tooling are extremely versatile, offering resistance to oils and greases, excellent surface touch, self-healing properties that reduce the visibility of small scratches, good electrical resistance and high transparency.

-

Can cellulose acetate be customized with specific colors and additives?+Cellulose acetate offers endless possibilities for both chromatic and technical customization. Thanks to Mazzucchelli’s extensive experience, customer requests can be fully satisfied.

-

Are there regulations or certifications for products made with cellulose acetate?+Mazzucchelli 1849 holds numerous certifications attesting to raw-material traceability, material sustainability, product biocompatibility, and compliance with major international standards, including REACH, RoHS, and Proposition 65. The company is also ISO 9001 certified, ensuring a solid and controlled quality-management system.

-

Where can I find more technical information on cellulose acetate granules?+All technical and physico-chemical information can be found on our website pages dedicated to cellulose acetate granules. Alternatively, you may contact us directly for full assistance and specific information for your projects.